“`html

Revolutionizing Maintenance: How Robotics Enhances Efficiency and Safety

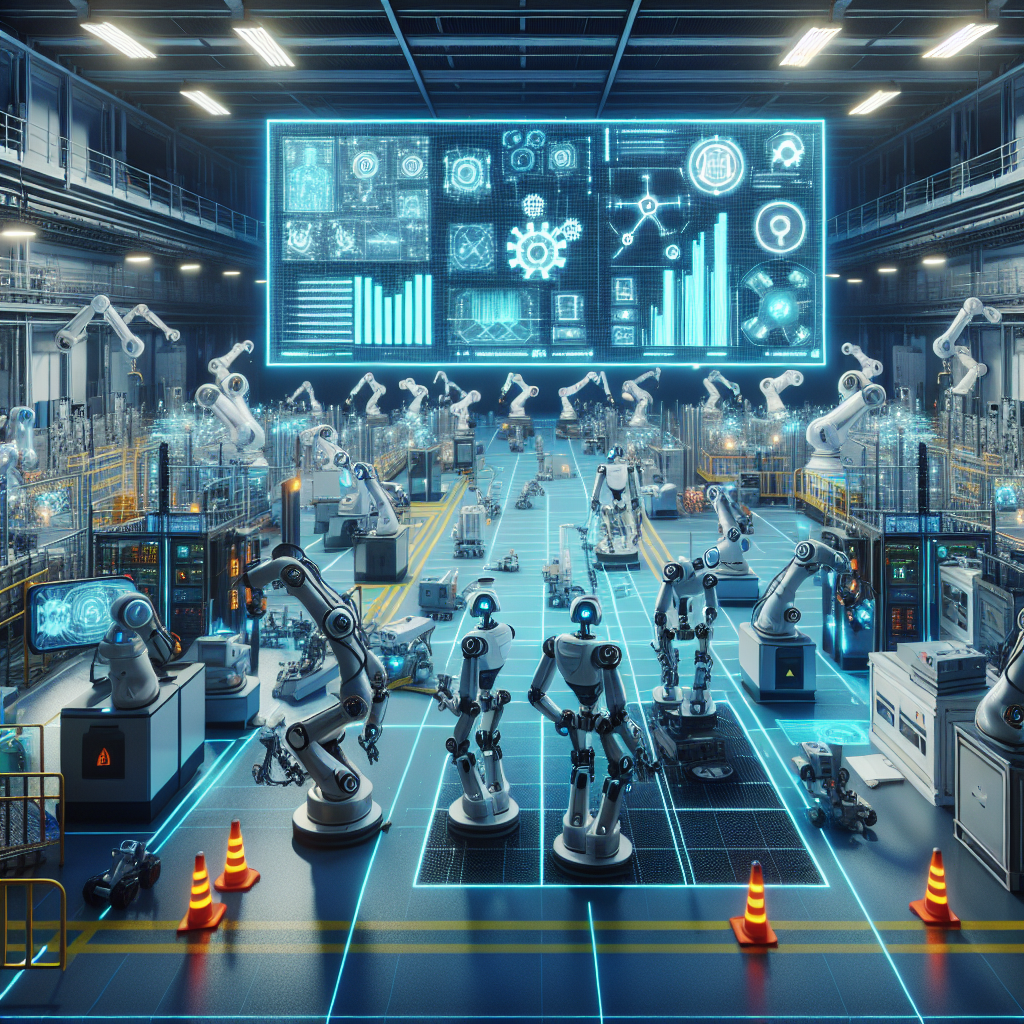

In an era where technology increasingly influences every aspect of our lives, industries across the globe are harnessing the power of robotics to transform traditional maintenance practices. From manufacturing floors to facility management, automated solutions are reimagining how companies approach maintenance tasks. This blog post delves into the significant benefits of robotics in modern maintenance and explores how these innovations enhance efficiency and safety.

Understanding Robotics in Maintenance

Robotics in maintenance refers to the application of robotic technologies to perform tasks typically carried out by human operators. These technologies range from simple automated systems to sophisticated AI-driven robots capable of learning and adaptation. Here are some key areas where robotics plays a crucial role in maintenance:

- Predictive Maintenance: Advanced sensors and algorithms allow robots to predict equipment failures before they happen, reducing costly downtime.

- Routine Inspections: Drones and autonomous vehicles can conduct inspections in hard-to-reach places, ensuring safety and thoroughness.

- Cleaning and Servicing: Robotic cleaners can maintain facilities without human intervention, keeping spaces sanitized and operational.

- Data Collection: Robots can gather data during maintenance tasks, providing valuable insights for future planning and decision-making.

Enhancing Efficiency with Robotics

One of the primary advantages of integrating robotics into maintenance operations is increased efficiency. This technology significantly reduces operational costs and improves productivity. Here’s how:

1. 24/7 Operations

Robots can work around the clock without needing breaks or sleep. This continuous operation means that maintenance tasks can be performed during off-peak hours, minimizing disruption to ongoing processes. For instance:

- Routine cleaning can occur after hours, ensuring a pristine work environment by morning.

- Predictive maintenance checks can take place during non-operational hours, preventing unexpected downtimes.

2. Reduced Human Error

Human error is one of the leading causes of accidents and inefficiencies in maintenance. Robotics reduces this risk by providing consistent and precise operations. Automation leads to:

- More accurate inspections, reducing the chances of overlooking critical issues.

- Consistency in cleaning processes, which helps maintain a safe environment.

3. Speedy Operations

Robotic systems can perform tasks significantly faster than human workers. For example:

- A robotic arm can complete assembly or maintenance tasks in a fraction of the time it would take a human.

- Drones can quickly assess the condition of rooftop equipment, relaying information in real time.

Prioritizing Safety with Robotic Innovations

The safety of employees is a principal concern in any maintenance operation. Robotics helps address safety issues effectively with the following advantages:

1. Hazardous Environments

Some maintenance tasks require access to hazardous or difficult environments—areas where human presence poses significant risks. Robotics can:

- Perform inspections or repairs in dangerous locations such as high altitudes or confined spaces.

- Handle materials deemed unsafe for humans, such as chemicals or heavy machinery.

2. Minimizing Workplace Injuries

Robots alleviate the physical demands of maintenance tasks, thereby reducing the chances of workplace injuries. They can:

- Lift and maneuver heavy objects, minimizing strain on human workers.

- Perform repetitive tasks, reducing fatigue and associated risks.

3. Enhanced Training and Supervision

Robotics can also aid in training human workers. By implementing robotic systems, companies can create safer training environments that:

- Allow workers to practice in controlled scenarios without risk.

- Enable real-time analysis of worker performance, leading to improved skills and reduced mistakes.

Future Prospects for Robotics in Maintenance

The potential of robotics to revolutionize maintenance is immense, and advancements in artificial intelligence (AI), machine learning, and IoT (Internet of Things) will likely propel these technologies further into the mainstream. As organizations embrace digital transformation, robotics will play a pivotal role in the following ways:

- Integration with AI: Intelligent algorithms can enhance decision-making processes and predictive maintenance capabilities.

- Remote Monitoring: Robotics powered by IoT can facilitate remote access and monitoring, allowing teams to manage systems without being on-site.

- Customization: Robots designed for specific tasks will become commonplace, allowing organizations to tailor their maintenance processes to unique needs.

Conclusion

The integration of robotics into maintenance practices is not just a trend—it’s a wave of transformative change that enhances efficiency and safety. As these technologies continue to evolve, organizations can expect significant improvements in productivity, cost savings, and employee satisfaction. As we look to the future, embracing robotics is no longer simply an option; it’s essential for businesses aiming to stay competitive in an increasingly automated world.

Are you ready to embrace the future of maintenance? Let the robots lead the way!

“`